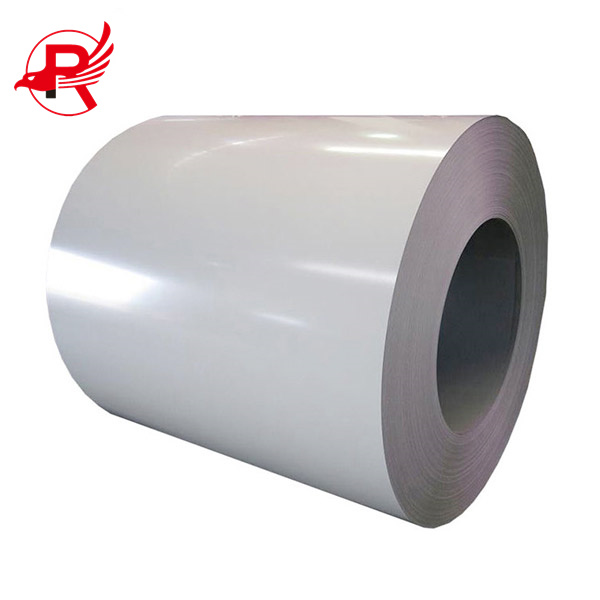

Bobina d'acer galvanitzat recobert de color PPGI prepintat laminada en calent Dx51D RAL9003 de 0,6 mm a la venda

PPGI, que significa ferro galvanitzat prepintat, és un tipus de bobina d'acer que s'ha recobert amb una capa de pintura. Aquest recobriment no només millora l'atractiu estètic de l'acer, sinó que també proporciona una capa addicional de protecció contra la corrosió i l'òxid. Les bobines d'acer PPGI s'utilitzen àmpliament en una varietat d'aplicacions, com ara cobertes, revestiments i construcció en general.

Un dels avantatges clau deBobina d'acer galvanitzat PPGIés la seva versatilitat. Estan disponibles en una àmplia gamma de colors i acabats, cosa que permet infinites possibilitats de disseny. Tant si busqueu un color atrevit i vibrant com un acabat més discret i natural, hi ha una bobina d'acer PPGI que s'adapta a les vostres necessitats. A més,Bobina PPGIes poden formar i modelar fàcilment, cosa que els fa ideals per crear components i estructures personalitzats.

Quan es tracta de durabilitat,Bobina d'acer galvanitzat prepintatsón insuperables. La capa galvanitzada proporciona una excel·lent protecció contra els elements, garantint que l'acer es mantingui en les millors condicions durant els propers anys. Això fa que les bobines d'acer PPGI siguin una opció rendible, ja que requereixen un manteniment mínim i tenen una llarga vida útil.

Pel que fa a l'aplicació,Bobina d'acer prepintadaSón adequats tant per a ús interior com exterior. Tant si voleu afegir un toc de color a la façana d'un edifici com si voleu crear una teulada duradora i resistent a les inclemències del temps, les bobines d'acer PPGI estan a l'altura de la tasca. La seva versatilitat i durabilitat les converteixen en una opció popular per a arquitectes, constructors i dissenyadors.

| Rang de gruix: | de 0,10 mm a 1,5 mm |

| Tipus de gruix: | Gruix total del recobriment (TCT), gruix del metall base (BMT) |

| Rang d'amplada: | de 700 mm a 1250 mm Amplada normal: 914 mm, 1000 mm, 1219 mm, 1220 mm, 1250 mm |

| Gruix/calibre del recobriment d'aliatge de zinc/55% d'alumini: | Rang de gruix del recobriment de zinc: de 40 g/m2 a 275 g/m2 / de Z40 a Z275 Recobriment d'aliatge de zinc i alumini: de 40 g/m2 a 150 g/m2/ AZ40 a AZ150 |

| Superfície metàl·lica base estructural: | Pell passada amb lluentons mínims Pell passada zero lluentons |

| Rang de gruix del recobriment de pintura: | Revestiment frontal: imprimació + capa superior: de 10 µm a 40 µm; Revestiment posterior/inferior: de 3um a 10um. |

| Color de la superfície: | Color superior/frontal: segons el número RAL requerit. Color posterior/inferior: gris molí |

| Tipus de capa superior: | Polièster (PE), polièster de silicona (SMP), polièster d'alta resistència (HDP), fluoropolímer (PVDF) |

| Condició de la superfície del recobriment | Revestiment comú PPGI Revestiment d'impressió PPGI PPGI en relleu |

| Classificat per ús: | Construcció a l'aire lliure Construcció interior electrodomèstic Altres |

| ID de la bobina: | 508 mm/610 mm |

| Pes de la bobina: | de 3 tones mètriques a 5 tones mètriques |

| Mostres: | Gratuït si està disponible |

Les bobines d'acer galvanitzat prepintades tenen una àmplia gamma d'aplicacions a causa de la seva durabilitat, resistència a la corrosió i atractiu estètic. Algunes aplicacions comunes inclouen:

Cobertes i revestimentsLes bobines d'acer galvanitzat prepintat s'utilitzen àmpliament en la indústria de la construcció per a aplicacions de cobertes i revestiments. La naturalesa duradora i resistent a les inclemències del temps del material el fa ideal per protegir els edificis dels elements.

Indústria de l'automòbilLa indústria de l'automoció utilitza bobines d'acer galvanitzat prepintat per a diversos components, com ara panells de carrosseria, peces de xassís i altres elements estructurals. La resistència a la corrosió i la formabilitat del material el fan adequat per a aplicacions en automoció.

ElectrodomèsticsLes bobines d'acer galvanitzat prepintat s'utilitzen en la fabricació d'electrodomèstics com ara neveres, forns i rentadores. La superfície llisa del material i la seva capacitat per suportar entorns durs el converteixen en una opció popular per als fabricants d'electrodomèstics.

MoblesLa construcció de mobles, inclosos armaris, prestatgeries i altres articles per a la llar, sovint utilitza bobines d'acer galvanitzat prepintades a causa de la seva resistència, versatilitat i atractiu estètic.

Tancaments elèctricsLa indústria elèctrica utilitza bobines d'acer galvanitzat prepintat per a la producció de tancaments elèctrics, aparells de distribució i panells de control a causa de la capacitat del material per proporcionar protecció contra la corrosió i els factors ambientals.

Senyalització i visualitzacióLes bobines d'acer galvanitzat prepintat s'utilitzen en la producció de senyalització, panells de visualització i elements arquitectònics a causa de la seva capacitat per mantenir el color i l'acabat al llarg del temps, fins i tot en entorns exteriors.

Nota:

1. Mostreig gratuït, garantia de qualitat 100% postvenda, suport a qualsevol mètode de pagament;

2. Totes les altres especificacions de PPGI estan disponibles segons les vostres necessitats

Requisit (OEM i ODM)! Preu de fàbrica que obtindreu de ROYAL GROUP.

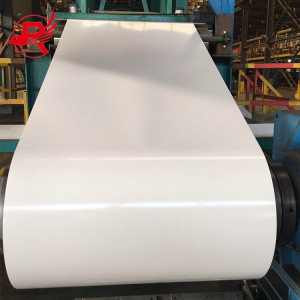

Primer adesenrotllador -- màquina de cosir, corró, màquina tensora, bucle de llibre obert, desgreixatge amb rentat amb bicarbonat -- neteja, assecat, passivació -- al principi de l'assecat -- tocat -- l'assecat inicial --acabat fi tu --acabat d'assecat --Refrigeració per aire i refrigeració per aigua -rebobinador looper -Rebobinadora -----(rebobinar per emmagatzemar-lo).

Placa electrogalvanitzada com a substrat, recoberta amb productes de forn de recobriment orgànic per a la placa electrogalvanitzada recoberta de color, com que la capa de zinc de la placa electrogalvanitzada és fina, normalment conté un contingut de zinc de 20/20 g/m2, per la qual cosa el producte no és adequat per al seu ús en la producció exterior de parets, teulades, etc. Tanmateix, a causa del seu bell aspecte i excel·lents propietats de processament, es pot utilitzar principalment per a electrodomèstics, àudio, mobles d'acer, decoració d'interiors, etc.

Transport:Express (lliurament de mostres), aeri, ferroviari, terrestre, marítim (FCL o LCL o a granel)

P: Sou fabricants de la UA?

R: Sí, som fabricants. Tenim la nostra pròpia fàbrica situada a la ciutat de Tianjin, Xina.

P: Puc tenir una comanda de prova només d'unes quantes tones?

R: Per descomptat. Podem enviar la càrrega per a vosaltres amb servei LCL (menys càrrega de contenidor)

P: Si la mostra és gratuïta?

A: Mostra gratuïta, però el comprador paga el transport.

P: Sou proveïdor d'or i feu garantia comercial?

A: Som proveïdors d'or de set anys i acceptem la garantia comercial.